Propriety Machinery

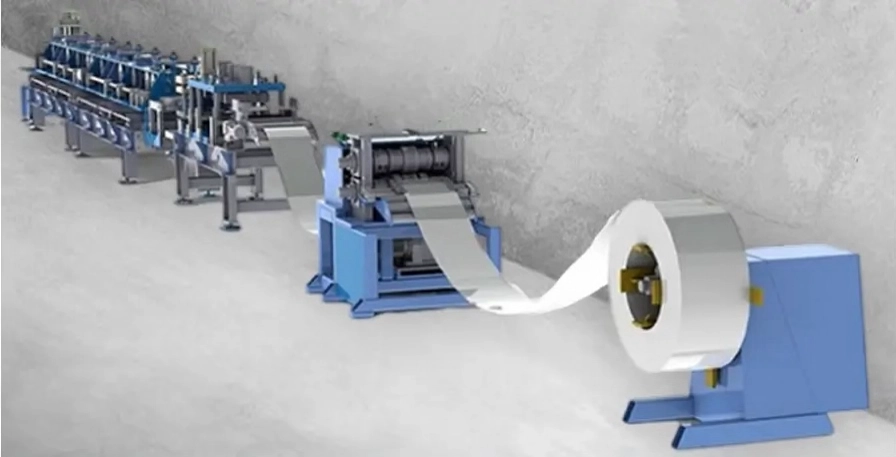

At NeoBuild, we specialize in design and manufacturing prefabrication machinery. We developed machines for production of various prefabricated structural elements. In particular, our team boasts a wealth of experiences in developing roll-forming machines, which play a critical role in producing high-quality building materials. By leveraging the latest technology and innovative design techniques, we create machines that are reliable, efficient, and easy to operate. Our roll-forming machines are engineered to meet the highest standards of quality and precision, enabling our clients to produce superior building materials that exceed their customers’ expectations.

With our expertise in design of prefabrication machines, we have become a trusted partner for clients looking to enhance their production capabilities and competitiveness. Our team of skilled engineers and designers works closely with our clients to develop customised solutions that maximize the machines productivity, efficiency, and profitability. From conceptualization to commissioning, we take a collaborative approach to ensure that every aspect of our clients’ manufacturing processes is optimised to meet their specific needs.

Our dedication to delivering innovative solutions that meet our clients’ unique requirements has made us a leading provider of fabrication machinery. We take pride in our ability to develop machines that are tailored to our clients’ needs and offer them a competitive edge in their industry. At NeoBuild, we are committed to helping our clients achieve their goals by delivering reliable, efficient, and high-quality machinery that meets the demands of their customers.

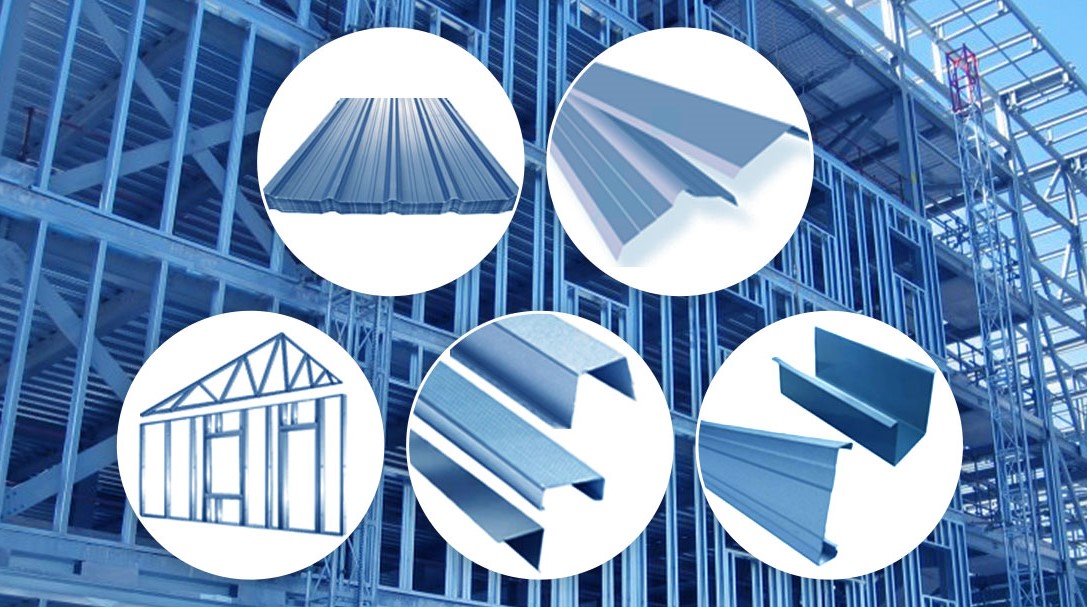

Neobuild design and produce various prefabrication machineries. They include LGS framing machine, LGS framing Accessory machine, Steel fabrication machines, and Fiber cement Machines.

In LGS framing machine, light gauge steel frame elements are manufactured. This machine is designed based on ASTM standard A1003. It takes structural steel sheet and form them into high strength C, Z or S shapes which are able to support heavy loads.

The light gauge steel is also called cold formed steel which comes from the process by which steel members are formed. Light Gauge Steel Frame components include wall systems, flooring systems, and roof systems. A load-bearing wall is the one that carries vertical loads or lateral loads resulting from the wind. These loads may act separately or in combination. Both internal and external walls may be load-bearing. Other types of walls include non-load-bearing walls, wall cladding, and partitions.

This is the same as LGS framing machine but designed to produce building accessories including Gutter, Fascia, Roof battens, Ceiling battens, Roof sheeting, Ridge cap, and Edge cover.

Steel fabrication machines are designed to produce various steel elements and structures, such as trusses, for buildings. There are several machines designed in Neobuild to cover the whole process of steel fabrication, including melting raw materials, mixing melted materials into steel, and forming the desired shape. This process is widely used by steel fabricators to generate all kinds of steel parts and components, including bar joists, ladders, grating, skids, universal beams, pipe racks, platforms, universal columns, industrial equipment, and more.

This steel fabrication machines includes six machines. They are: (a) Flame Cutting Machine; (b) Assembly, Welding, and Straightening Machine; (c) H Beam Cutting Machine; (d) 3D Beam Drilling Machine; (e) H Beam Shot Blasting Machine; and (f) Box and Pipe Section Machine. Each of these machines serves a specific function and contributes to the overall production capacity of the steel prefabrication workshop.

Brisbane Office:

40 Kurzok Place, Richlands

QLD 4077

Tel: (07) 3096 0300

Gold Coast Office: Shop 9, H20 Broadwater, 13 welch St, Southport, QLD 4215.

Sydney Office:

Level 5/7 Eden Park Dr, Macquarie Park NSW 2113

Tel: (02) 9487 2862

Melbourne Office:

25 Enterprise way, Sunshine West, 3020, VIC

Tel: (04) 35 222 605

Canberra Office:

130/41 Chandler Street, Belconnen, ACT, 2617

Tel: (04) 6600 4993

© Copyright Neobuild Group