Prefabrication Facilities

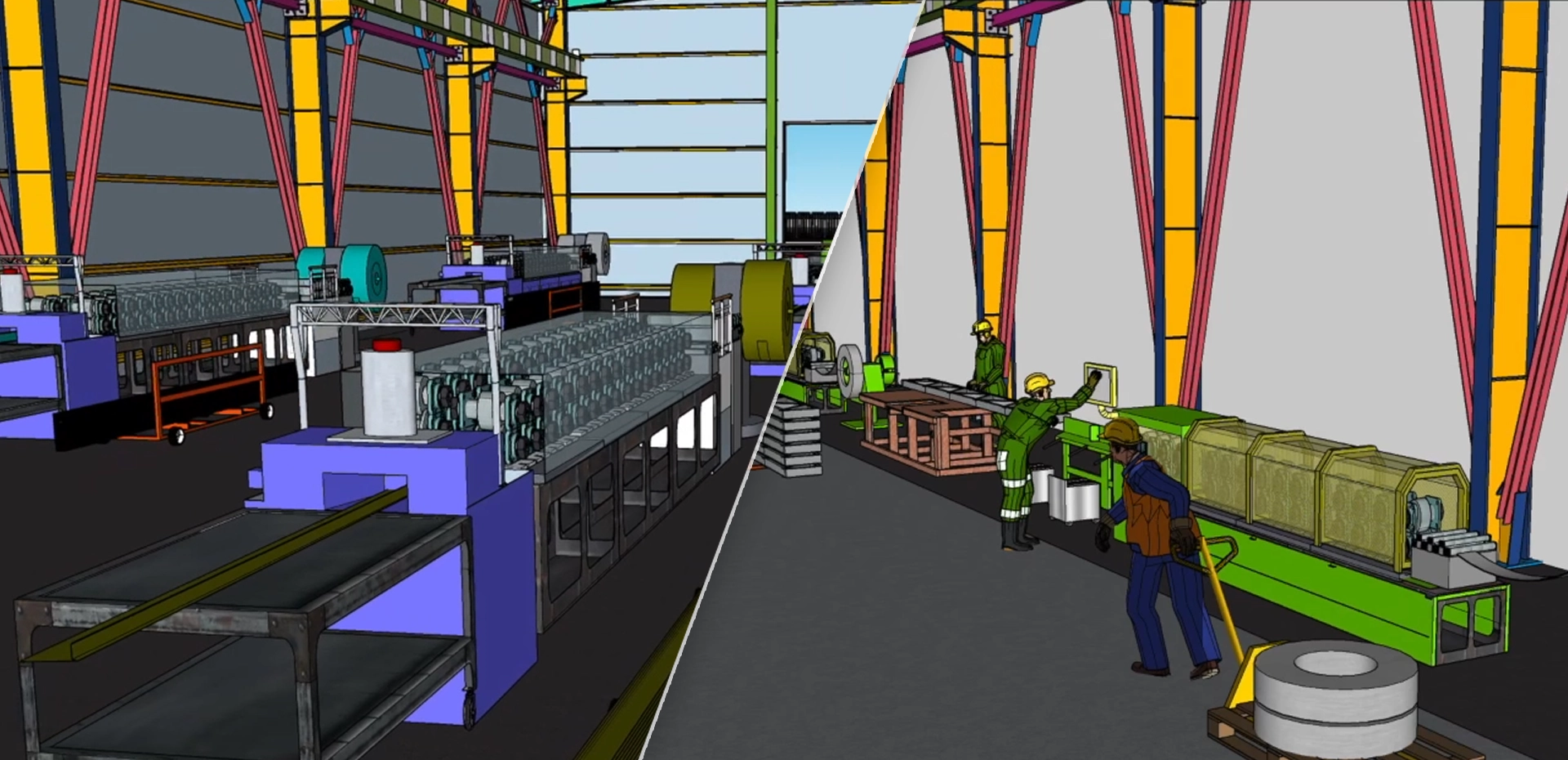

NeoBuild specializes in designing and establishing prefabrication plants that cater to the unique requirements of its clients. We cover all the steps for setting up prefabrication facilities; they include feasibility study, selection of suitable locations, design of sheds and workshops, design and setting up of required prefabrication machines, and design of optimum operation plans. Our team of skilled engineers and designers collaborate closely with our clients to develop tailored solutions that enhance their productivity, efficiency, and profitability. With a proven track record, we are committed to delivering the best results for our clients.

From conceptualization to commissioning, NeoBuild’s expertise in designing and establishing prefabrication plants encompasses the entire process. We work in partnership with our clients to ensure that every aspect of the plant meets their specific needs. Our collaborative approach enables us to optimise workflows, reduce production costs, and maximise output; resulting in efficient and profitable prefabrication plants. We support our client even after establishment (i.e, during operation process) to ensure productivity and efficiency of the designed plans.

At NeoBuild, we are passionate about delivering customized solutions that provide our clients with a competitive edge. We take pride in our ability to design and establish prefabrication machines and plants that are tailored to our clients’ unique requirements, ensuring they receive maximum value from their investment. Our focus on delivering exceptional results has earned us a reputation as a trusted partner for businesses looking to enhance their manufacturing processes.

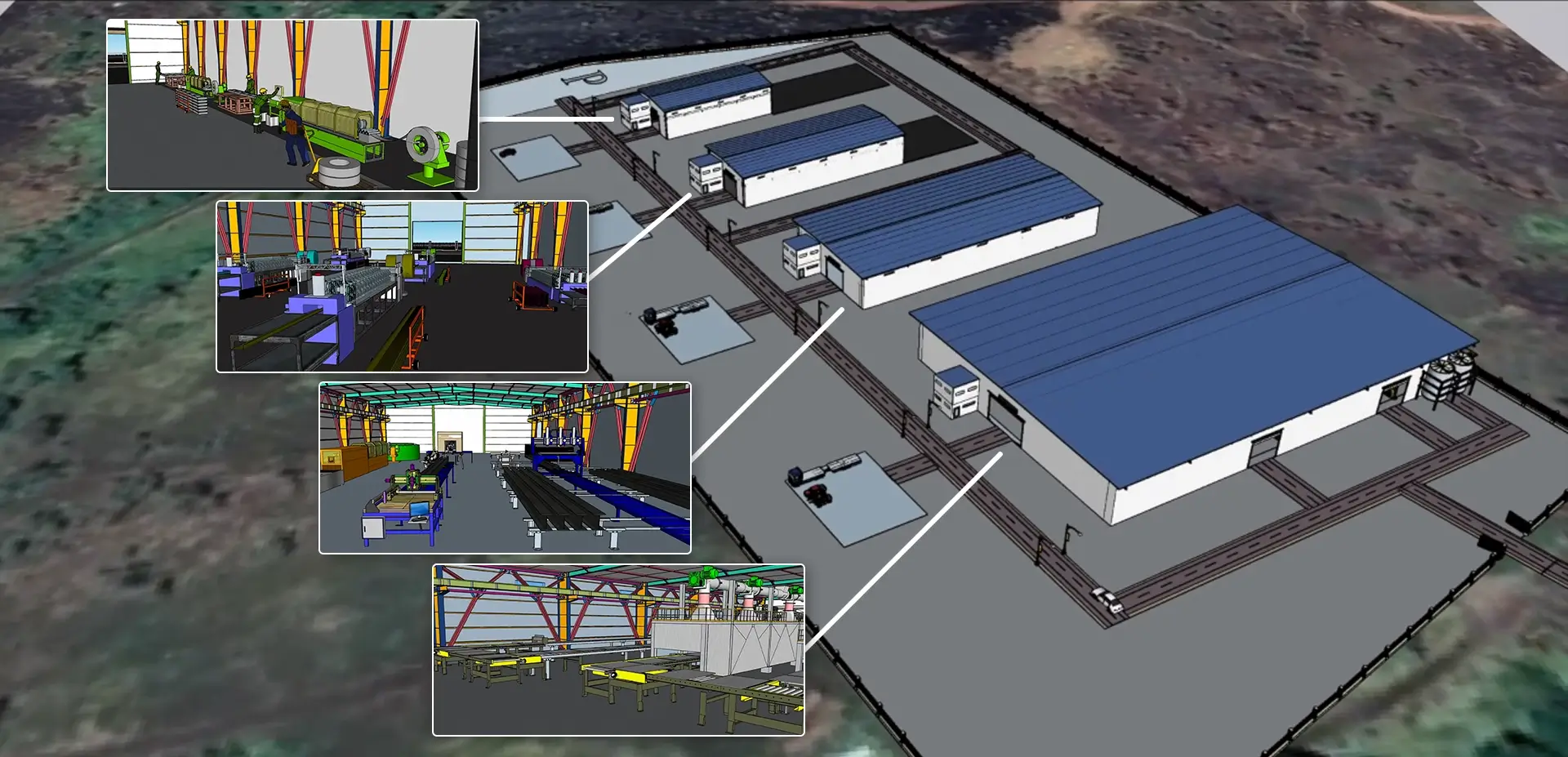

Neobuild are expert in establishing prefabrication facilities in medium to large sizes. Prefabrication facilities are design based on clients’ requirements and conditions. They include: type of house needed, availability of materials, current construction methods, machinery and equipment available on construction sites, available workforce, environmental conditions, and regulations (in regard to construction and transportation).

The medium size prefabrication facilities include only LGS framing machines for producing materials for structural light steel residential and non-residential buildings. They include two types of machines LGS framing machine and LGS framing accessory machine.

The large size prefabrication facilities include GLSF machines (for main steel structural elements and accessories), steel fabrication machines, and gypsum drywall machines, and sandwich panel machines.

In the prefabrication facilities, the project begins at the design phase and the manufacturing of building components begins once the design is finalized. It should be noted that we follow the local building codes and zoning regulations. In the prefabrication facilities, the prefabricated components are built in a controlled offsite factory environment while site excavation and grading is going on at the same time. The amount of work (60% – 90%) performed in the factory can vary based on owner requirements.

The process begins in the design center where specifications are programmed into automation software that systematically produces each component at a defined station. This design and build technology is very flexible and facilitates a broad range of architecture. Framing begins with the sorting and selecting of fresh engineered studs from inventory. The plant should use real-time inventory controls to move studs, trusses, joists, and plywood through production efficiently. This permits the bulk purchase of materials and prescribed dimensions to ensure higher quality construction with less waste. Flooring begins with the placing of joists into an autoloader so they can be picked and placed robotically onto the automated finishing line.

Upon completion of the prefabricated elements, they are prepared for transportation. Fabricated buildings components are shipped on chassis integrated into the structure or carriers towed by trucks. Due to the need to transport the prefabricated components to the final site, each componentare built to independently withstand travel and installation requirements (e.g., high winds, manipulation by cranes). Transportation of the prefabricated components depends upon some important factors such as the cost and method of transport, travel distance, and weight. It usually isn’t feasible to ship modules far due to road size and load restrictions.

Brisbane Office:

40 Kurzok Place, Richlands

QLD 4077

Tel: (07) 3096 0300

Gold Coast Office: Shop 9, H20 Broadwater, 13 welch St, Southport, QLD 4215.

Sydney Office:

Level 5/7 Eden Park Dr, Macquarie Park NSW 2113

Tel: (02) 9487 2862

Melbourne Office:

25 Enterprise way, Sunshine West, 3020, VIC

Tel: (04) 35 222 605

Canberra Office:

130/41 Chandler Street, Belconnen, ACT, 2617

Tel: (04) 6600 4993

© Copyright Neobuild Group